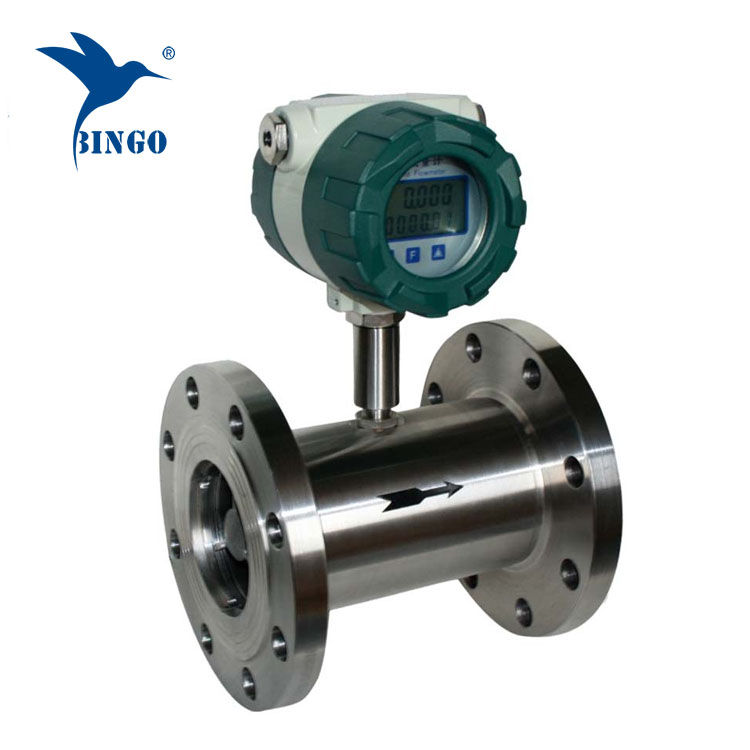

Quick Details

Product Name: stainless steel deionized water turbine flow meter sensor

Accuracy: ±0.5%

Power supply: 100-240VAC, 50/60HZ

Application: Measuring Fluid

Output: 4-20mA/Pulse

Ambient Temperature: -10℃~120℃

Conductivity: water 20μS/cm other medium 5μS/cm

connection type: flange, tri-clamped, union type

Product Feature

1.The sensor is with hard alloy bearing thrust type, which may guarantee the precision and improve the wear resistance 2.performance as well. Digital Hydraulic Turbine Diesel Flow Meter

3.Simple and firm structure, easy for installation and dismantling.

4.Wide range of measuring with very lower flow velocity limit.

5.Small loss of pressure,fine repeat .LCD Oil Turbine Flow Meter Calibration Procedure

6.Ability and high precision.Digital Hydraulic Turbine Diesel Flow Meter

7.High resistance to electromagnetic interference and vibration.

specification | |

Size& Process Connection | Thread connection:DN4, 6, 10, 15, 20, 25, 32, 40,50, 65, 80, 100; |

Flange connection:DN15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 200 ; | |

Clamp connection:DN4, 6, 10, 15, 20, 25, 32, 40, 50, 65, 80 ; | |

Accuracy/Range ratio | ±0.5%R; 1:10; 1:15; 1:20 |

Sensor Material | SS304, SS316L |

Ambient Conditions | Medium temperature: -20℃~+120℃; Atmospheric pressure: 86Kpa~106Kpa Ambient temperature: -20℃~+60℃; Relative humidity: 5%~90% |

Output | Pulse ,4-20mA, RS485 communication, HART protocol |

Power Supply | A: +24VDC, for 4-20mA , pulse, RS485 output B: 3.6 V lithium battery, battery voltage: 2.0 V ~3.0 V |

Electrical connector | Standard: 3-core wire cable; Explosion-proof L: M20*1.5 |

Explosion -proof class | ExiaIICT4 or ExdIIBT6 |

Protection class | IP65 or higher(customized) |

Flow Range

A turbine flow meter is constructed with rotor and blades that use the mechanical energy of the fluid to rotate the rotor in the flow stream. Blades on the rotor are angled to transform energy from the flow stream into rotational energy. The rotor shaft spins on bearings: when the fluid moves faster, the rotor spins proportionally faster. Shaft rotation can be sensed mechanically or by detecting the movement of the rotor blades

Rotor movement is often detected magnetically, where movement of the rotor generates a pulse. When the fluid moves faster, more pulses are generated. Turbine flow meter sensors detecting the pulse are typically located external to the flowing stream to avoid material of construction constraints that would result if wetted sensors were used. The RPM of the turbine wheel is directly proportional to the mean flow velocity within the tube diameter and corresponds to the volume flow over a wide range

A flow transmitter processes the pulse signal to determine the flow of the fluid. Flow transmitter and sensing systems are available to sense flow in both the forward and reverse flow directions. High accuracy turbine flowmeters are available for custody transfer of hydrocarbons and natural gas. This fuel flow meter often incorporates the functionality of a flow computer to correct for pressure, temperature, and fluid properties in order to achieve the desired accuracy for the custody transfer application.

Turbine flow meters have moving parts that are subject to degradation with time and use. Abrupt transitions from gas flowmeter applications to liquid flowmeter use should be avoided because they can mechanically stress the flowmeter, degrade accuracy, and/or damage the flow meter. These conditions generally occur when filling the pipe and under slug flow conditions. Using the turbine flow meter for two-phase flow conditions such as steam flow metering applications can also cause a turbine flow meter to measure inaccurately.

A turbine flow meter measures the velocity of liquids, gases and vapors in pipes, such as hydrocarbons in fuel flow measurement, chemical flow metering, water flow metering, cryogenic liquid flow metering, air or gas flow metering, and general industrial flow metering. High accuracy turbine flowmeters are available for custody transfer of hydrocarbons and natural gas. A mass flow computer is often used in custody-transfer applications to correct for pressure, temperature and fluid properties in order to achieve the desired accuracy. Other low viscosity applications are tap and demineralized water, fuel flow meter solvents, and pharmaceutical fluids