Basic Info

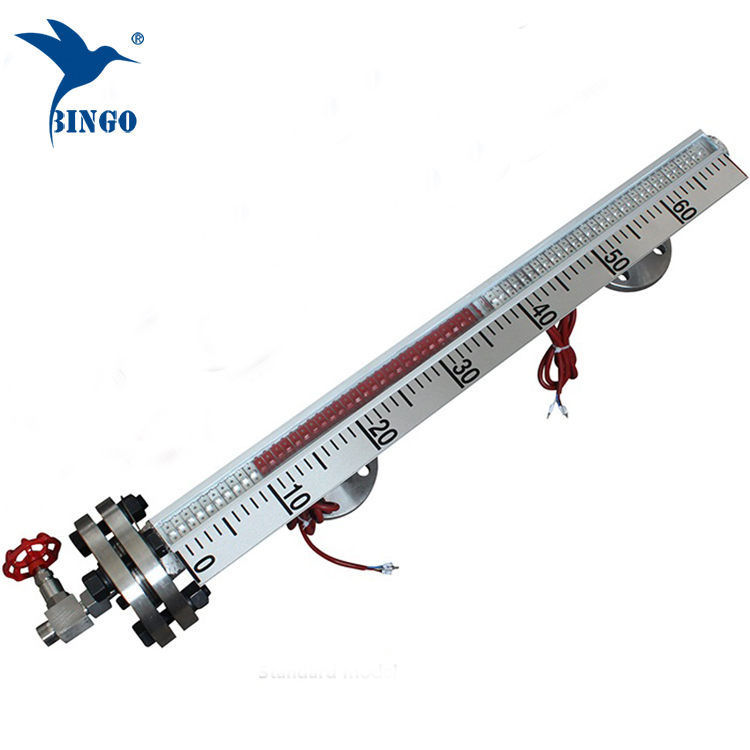

Model NO.: UHC

Warranty: 1 Year

Certification: CE, UL, RoHS

Material: CS, Ss304, 316L, Steel Lined with PP, PTFE

Process Temperature: -40 to +450 Degree C

Mounting: Side, Top, Side-Top Flange or Thread

Level Switch: High Level, High High Level, Low Level, Low Low

Swtich Type: COM, No., Nc. Control Switch

Transmitter: 4~20mA Output Signal

Float Working Density: >0.5g/cm3

Measure Range: <10m

Norminal Pressure: 1.0MPa, 1.6MPa, 2.5MPa, 4MPa, 6.3MPa, 10MPa, 16MPa

Working Temperature: -40~450 C

Valves: with Drain Valve, Vent Valve

Transport Package: Wooden Case or Carton

Specification: 0~10m

Product Description

- Easy to install, no extra piping required in most applications

- Magnetic level gauge Visual level indication up to 30m, sections made suit for delivery. Magnetostrictive level indicator can reach 30m measure range with cable insertion.

- Ideal for high-temperature, high-pressure and corrosive applications.

- Magnetostrictive and radar transmitter options for non-invasive and/or redundant level control.

- Available with HART, 4~20mA, and level switches.

| Float Cage Material | SS304, SS316, PTFE, PP, PVC, PVDF |

| Max. Centre to Centre Distance | 6000 mm, greater lengths on request |

| Connecting Flanges | According to DIN or ANSI B16.5 |

| Temperature of Liquid | 450ºC (Max.) for SS, 80ºC (Max.) for PVDF 60ºC (Max.) for PVC, 50ºC (Max.) for PP |

| Specific Gravity | Min. 0.45 |

| Scale | Graduated in cm, Aluminium or SS304 |

| Measuring Accuracy | +/- 5 mm |

Floats UHC Floats are specifically calibrated to match the conditions of the vessel. The density, operating pressure and temperature are taken into account, ensuring that the inferred level is accurate and repeatable.

Floats material: SUS304, SUS316, PTFE, PP, and Titanium.

Anticorrosive material: such as stainless steel SUS 304 or SUS316L, Teflon PTFE, polypropylene (PP), FRP and advanced tech. application such as X-ray detection, cold-rolling broaching weld, all ensure that the product can be adapted to any demand at site. Additional blow off valve can be added onto the bottom sealing type of the tube when necessary.