Basic Info

Warranty: 1 Year

Certification: CE, RoHS

Material: SS360L

Process Temperature: -40~300℃

Measuring Range: 0.3 ~9m

Accuracy Class: 5mm F.S.

Min Medium Density: 0.5~3.0kg/L, or 0.8~3.0kg/L

Viscosity: < 5000mpa.S

Pressure Standard: 4.0mpa, 6.4mpa, 10.0mpa, 16.0mpa

Indicator Scale: Cm/M Linear, Inch/Feet, % (or as Required)

Indicator Protection: IP65

Processing Temperature: 150-450 (Deg. C)

Remote Output: 4~20mA

Flange Connection: Dn25, Pn4.0, as Required

Transport Package: International Export Carton Packing, Water Proof

Specification: CE

Product Description

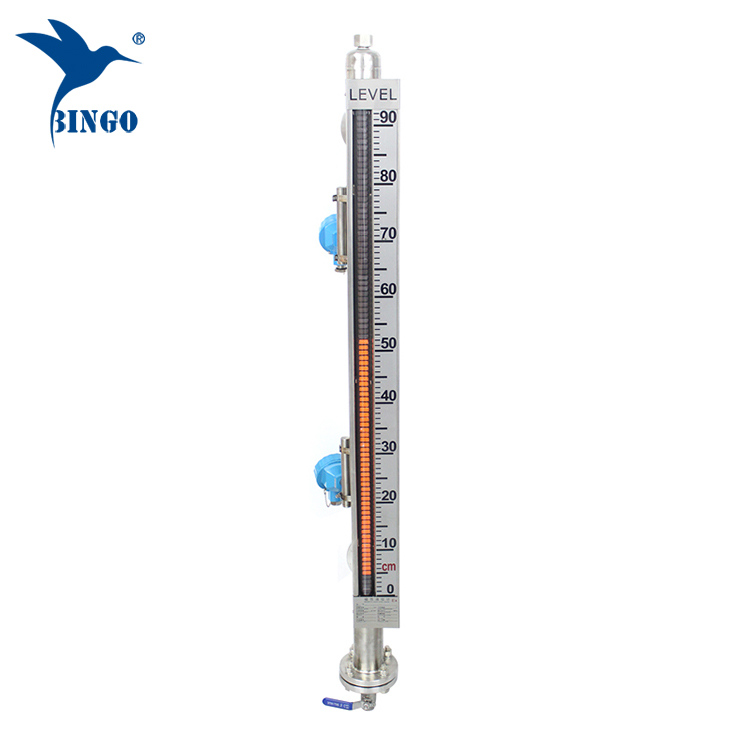

Tosilon Magnetic Boiler Level Gauge with Float Switch for Water (CE, Ex Approved)

Design and Manufacturing according to CE Standard

Introduction

TMG86 level Gauge is used for measuring liquid levels in open or pressurized tanks. Due to its special design, it is particularly suitable for use in connection with aggressive, noxious or flammable substances and tough service conditions.

No power is required for local liquid-level indication. Optionally, the unit can be equipped or retrofitted with an electrical analogue level transducer system and/or limit switches.

Performance

- Simple, Rugged, Advanced technology, Fashionable design

- Withstanding pressure, indicating part and measuring part is insulated by sealing

- Suitable for tough operating and environment conditions

- Reliable for liquid/gasoil, at density≥ 0.5kg/l

- Big bar scale, easily read

- Various versions, with inner PTFE or hard plastics and so on

- Pressure: Standard ≥ 4.0MPa, middle pressure: 6.4MPa, high pressure: 10.0MPa, 16.0MPa

- Temperature: Standard ≤ 150 oC, middle temperature ≤ 200 oC, high temperature ≤ 450 oC

- Measure interface, at density difference ≥ 0.1kg/l

- Changeable indicator, optional limit switches and remote transducer system remote current output: 4~20mA

Measuring Principle

The unit operates on the principle of communicating tubes. The measuring tube is connected as a side vessel to the tank such that the same conditions are obtained in the tube as those in the tank.

The float is equipped with a system of permanent magnets to transmit measured values to the local indicator. The magnet system of the float activates the magnetic flaps according to the liquid level, or a movable follower magnet in the indicating section of the indicator.